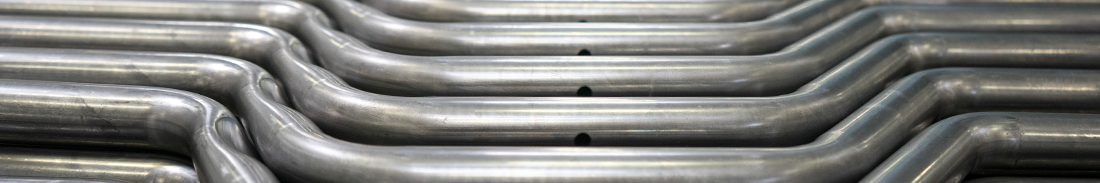

Precision Bending

A Dime A Dozen

Tube bending firms are a dime a dozen; so what sets us apart? Pairing the bending operation with our laser tube cutters, rather than more traditional methods, reduces the production of featured parts from an average of six operations down to just two by eliminating extraneous saw, deburr, and punch operations.

Variety Of Capabilities

Our benders can handle virtually any shaped tube including round, oval, rectangle, and square. With the addition of our large-capacity, rotary-draw tube bender we can bend up to six inch round or four inch square tube to the customer’s exact specifications. The “big bender” can handle a maximum centerline radius of 18 inches. Most other bending plants can’t come close.

With a combined 30 years of experience, our bending engineers and technicians can facilitate the production of complex components with ease:

- Single and multi-plane tubes

- Varying wall thicknesses

- Mandrel and rotary draw bending

- Variable radius bending

- Aluminum and steel materials

“Our team is committed to meeting our customers’ requirements through our dedication to continuous improvement and by delivering world-class quality products and services!”

“Our team is committed to meeting our customers’ requirements through our dedication to continuous improvement and by delivering world-class quality products and services!”